Why Edge Computing is Needed for Real-Time Decisions

Companies today are looking for ways to streamline their operations effectively without any mix up. Edge computing fixes the delay problem that shows up when factories or remote sites depend only on the cloud.

You can’t run a high-speed assembly line or monitor a fast-moving turbine with analytics that arrive seconds too late. Processing data directly at the edge keeps decisions instant and operations stable.

When sensors, robots, and control systems get insights immediately, you remove bottlenecks, reduce waste, and catch issues before they become emergencies. The advantage is being able to do all this without flooding your cloud storage with unnecessary raw data.

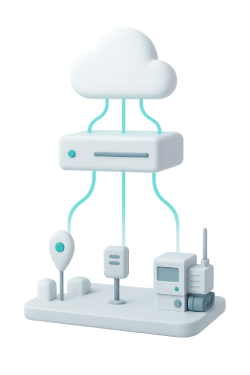

What Edge Architecture Looks Like

A good edge setup feels simple on the outside but has a lot going on underneath. Every component has a layered system where each layer handles the right amount of processing.

Let’s have a closer look what this looks like on the inside:

The Device Layer

This part of the design is where your sensors, actuators, PLCs, and industrial machinery live. Their job is to collect raw data nonstop involving temperatures, vibrations, pressure changes, cycle speeds, and anything else the operation needs. At this layer, the focus is on capturing clean and consistent data.

The Edge Gateway Layer

Moving on, you have the “mini data center” at the edge. What this component does is to filter, transform, and run analytics models on the device data. Instead of sending everything to the cloud, it sends only what’s important.

The Cloud Layer

The cloud layer sits at the top and focuses on providing long-term storage, heavy analytics, retraining pipelines, dashboards, and enterprise-wide coordination. While the edge handles immediate decisions, the cloud handles historical trends, optimization projects, and lifecycle management of all edge workloads.

How Industrial Teams Use Edge Analytics

Several Industries have evolved and stuck to relying on edge analytics when timing is important. If waiting even a moment could damage equipment, delay production, or put workers at risk, processing at the source becomes essential.

Here are common situations where this system comes in handy:

Predictive Maintenance

Machines generate noise long before they fail. These sounds could come in tiny vibration shifts, strange temperature spikes or irregular energy consumption. Edge models catch those changes instantly so they are able to schedule repairs precisely when they’re needed without reacting late or too early.

Quality Control

On production lines, edge devices monitor product quality in real time, checking measurements, shapes, weights, and visual defects. If something goes off-spec, it’s easy to make adjustments immediately rather than after hundreds of products are already flawed.

Energy Optimization

Factories waste a surprising amount of energy without noticing. Edge analytics highlights unusual power usage and automatically fine-tunes machines to reduce consumption without affecting output.

Safety Monitoring

In high-risk environments, milliseconds matter. Edge systems track dangerous gas levels, detect hazardous temperature spikes, and identify unsafe equipment behavior. Alerts fire instantly so operators can respond before anyone is at risk.

Quality Control

On production lines, edge devices monitor product quality in real time by checking measurements, shapes, weights, and visual defects. If something goes off-spec, adjustments are made immediately rather than after hundreds of products are already flawed.

Models for Distributed Analytics

Running analytics across multiple locations sounds complex, but distributed models make it manageable. The primary idea is to put the fast logic at the edge, and keep the heavy logic in the cloud.

To make sure this process is possible, here’s the pattern used:

Model Training in the Cloud

Because the cloud has the storage and computing power, this is where machine learning models get trained. You feed it historical data from every site, which helps the model spot patterns that a single location would miss.

Model Deployment at the Edge

After training, the models get pushed to edge gateways. These models run directly on live machinery data and update themselves as conditions change. If there’s no internet, they still work fine.

Feedback Loop Between Edge and Cloud

Insights from the edge travel back to the cloud to help retrain and improve the models over time. It’s a cycle where the pattern is to train, deploy, learn and finally, improve

Pairing Edge Workloads with Cloud Services

Most companies don’t pick between edge and cloud. The common method they employ is to use both. And when you combine them the right way, you get the best of two worlds Here’s what you get when you do this:

Real-Time Decisions at the Edge

You keep the fast, operational intelligence close to the machines. Nothing waits on slow networks or server delays.

Deep Analysis in the Cloud

The cloud handles large-scale pattern recognition, financial forecasting, resource planning, and anything that doesn’t require split-second timing.

Unified Monitoring Across All Sites

Even when each factory or plant runs its own edge system, the cloud brings everything together so leaders can compare performance and spot trends across locations.

Benefits of Edge with Industrial Analytics

When companies use edge computing the right way, the improvements show up everywhere across various aspects. Most people do not realize the advantage in combining these systems together, so let’s break them down.

Instant Insights

One of the biggest wins is how fast insights become available. Instead of sending sensor data to the cloud, waiting for it to be processed, and hoping the results come back in time, the edge does the thinking right there on the factory floor.

If a motor vibrates unusually or a temperature reading spikes, the edge system reacts right away. It doesn’t wait for a remote server to confirm whether something is wrong. This instant feedback loop helps teams jump on issues early, avoid downtime, and keep production stable hour after hour.

Better Machine Performance

Industrial machines behave more efficiently when analytics sit next to them. Edge systems can just play a supporting role by adjusting operating conditions based on what’s happening right now, not hours later.

Here are some useful case scenarios where this system would be effective:

- If a conveyor is running too fast, edge analytics can slow it down before it causes jams.

- If a robotic arm is drawing too much power, the system can adjust its motion path instantly.

- If a pump is overheating, the edge can trigger cooling or shut it down before it fails.

Higher Safety Standards

A lot of industrial IOT risks come from events that escalate quickly without solutions. You cannot rule out the possibility of gas leaks, temperature surges, pressure irregularities, equipment malfunctions. However, an edge system catches these signals the moment they happen.

Because alerts fire instantly, operators have more time to respond and prevent injuries or bigger hazards. It's always reassuring to know that a tool can help improve workplace safety, especially in dangerous environments like mining, oil and gas, heavy manufacturing, and chemical plants.

Improved Reliability During Outages

The cloud is powerful, but it depends on constant connectivity. If you lose internet access for even a short time, cloud-driven operations can stall. Edge computing solves that problem by keeping critical processes running locally.

Even if the network goes down:

- Machines keep reporting data.

- Analytics models keep running.

- Control systems stay active.

- Alerts still trigger.

You don’t get that “everything froze” moment that used to happen with cloud-only system

Challenges Enterprises Must Prepare For

Whenever a company decides to bring analytics to the edge, the benefits sound amazing, but the reality is that it comes with challenges you can’t afford to ignore. These aren’t deal-breakers, but they’re the kind of things that cause headaches if you don’t plan ahead.

Let’s break them down so you get an idea on what to expect:

Complexity of Distributed Systems

One thing nobody tells you upfront is how quickly complexity creeps in once you push analytics out to multiple edge locations. With the cloud, everything lives in one place. With the edge, you suddenly have dozens, and up to hundreds of devices doing their own processing.

Each node needs updates. Each node needs security. Each node needs monitoring.

If you don’t set up strong automation and orchestration tools early on, managing these distributed systems becomes overwhelming. This doesn’t mean that the edge is messy, far from it. It’s just that it scales differently, and enterprises need to treat it like the multi-location ecosystem it really is.

Strong Security Across All Edge Devices

Security becomes a bigger deal at the edge because data isn’t staying locked inside a cloud environment anymore. Now it’s spread across factory floors, remote equipment, vehicles, or small industrial PCs tucked in corners of your facilities.

Every edge device becomes a potential entry point.

Every sensor becomes a piece of the attack surface.

Dealing with Hardware Limitations

Cloud servers are powerful but the case isn’t always the same for edge devices. They usually have limited compute power, limited storage, and limited energy efficiency.

This forces enterprises to rethink how models are built and deployed. Heavy AI workloads might work perfectly in the cloud but struggle to run on a small edge gateway.

So, teams often need to:

- Compress models without losing accuracy

- Use lighter algorithms

- Balance workloads between edge and cloud

Reliable Connectivity Between Edge and Cloud

Even though the edge can run independently, it still relies on the cloud for training models, managing devices, storing long-term data, and coordinating updates. That means you need a stable link between the edge and your cloud environment.

- Industrial environments aren’t always predictable.

- Some facilities have network dead zones.

- Some operate in remote regions.

- Some rely on old network setups that were never designed for modern workloads.

If the connection becomes unstable, syncing data and deploying updates becomes messy. A smart enterprise plans for both strong connectivity and graceful fallback when the network goes down.

Final Thoughts

When you look at everything edge computing brings to industrial analytics, it’s clear why so many enterprises are shifting toward it. You get faster insights, stronger automation, fewer delays, and a level of real-time awareness that cloud-only setups simply can’t match.

It’s a shift that’s reshaping factories, utilities, logistics hubs, and every industry that depends on real-time decisions.

Quick Links

IoT = Internet of Things and IIoT = Industrial Internet of Things. Here are some examples of real-life applications in both the Consumer and Industrial markets. Just some examples.#infographic by @antgrasso via @antgrasso_IT > #IoT #IIoT pic.twitter.com/mYfBpF5WPn

— Antonio Grasso (@antgrasso) October 4, 2020